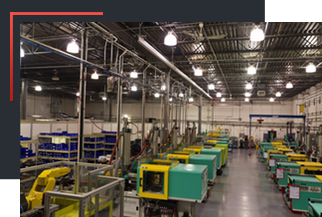

Our advanced Chicagoland headquarters facility houses the equipment and technicians necessary to design and manufacture a variety of automated machining solutions. We also have a long standing competency in the service, repair, and enhancement of existing metalworking technology.

Facilities include:

- Engineering lab equipped with the latest precision design software

- Precision machining centers (tolerances of + 0.0001)

- Temperature controlled clean room space for assembly

- Super precision measuring equipment

- Precision balancing equipment with electronic database documentation

- Vibration analyzing technologies

- Customizable test cells for precise runoff specifications

Although the true talents of our team are continuously being revealed, Dynomax can provide support in:

- Application consulting, including concept feasibility studies.

- New spindle design (using the latest of electronic 2D and 3D drawings.

- New spindle manufacturing (components and complete spindle systems).

- Spindle services (including everything from repairs to spindle enhancements)

- Systems integration assistance with controls and spindle system hardware